Description

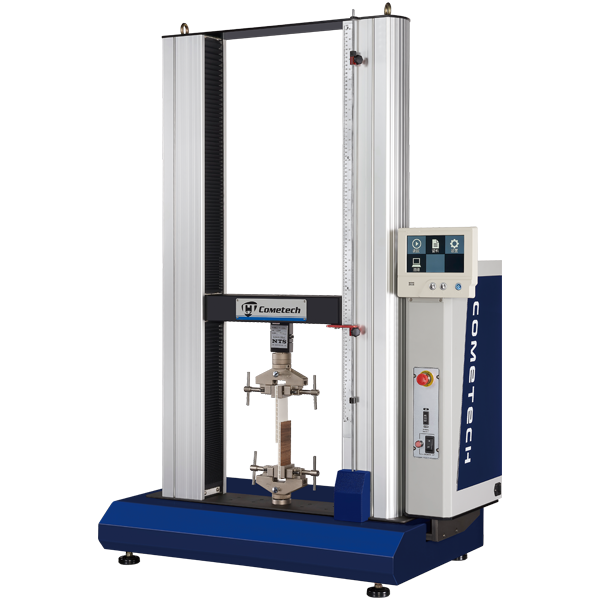

QC-526D2 is equipped with a 7-inch TFT touchscreen that enables standalone testing and supports an optional micro-printer for instant result printing. It is well-suited for production environments or applications requiring rapid testing. Its 20 kN capacity and generous test space make it ideal for both routine production checks and testing of larger or bulkier samples, offering excellent flexibility for future testing needs.

A specialized motor control and computing system allows the DC motor to deliver performance comparable to that of a servo motor. During crosshead movement, the system automatically adjusts speed to achieve optimal control accuracy. Test speed settings are fully digitalized, and testing can be initiated with a single touch, enhancing both operational convenience and efficiency.

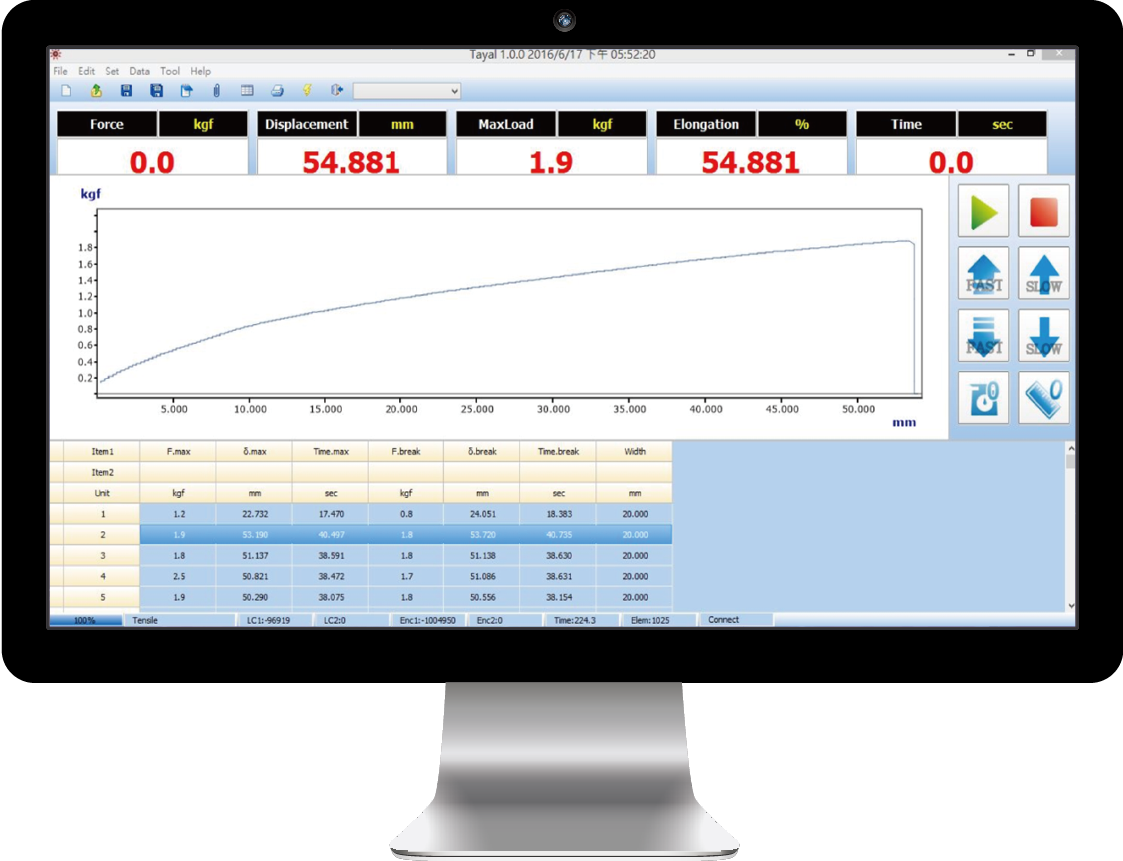

The D2 software works seamlessly with Windows, enabling the machine to perform tensile, compression, bending, peeling, and various other tests. The interface is straightforward and user-friendly, supporting multiple languages, engineering units, real-time curve display, and comprehensive data reporting, thus providing users with greater flexibility and control.

Conform to Standards

- ISO 7500-1

- ASTM E4

- ASTM D-76

- DIN 5122

- JIS B7721/B7733

- BS EN 1002-2

- BS 1610

- GB/T 228

- ASTM D790

Industry

Rubber, Plastic, Paper, Textile, Metal, Wood, Tape, Electronics, Package, Medical, Construction and others

Application

ASTM D882 Film Tensile Test

ASTM D638 Plastic Tensile Test

ASTM D412 Rubber Tensile Test

ASTM D1000 ASTM D3330 Tape Peeling Test

ASTM D1894 Coefficient of Friction Test

ASTM F1306 Plastic Film Puncture Test

ISO 13934-1 Tensile properties of fabrics

Top Load Testing

Test Solutions for Bottle Industry

ASTM D3787 | ASTM D6797 Textile Puncture Testing

Catalog Download

QC-526D2 Universal Testing Machines

Specifications

Max. Capacity

20 kN

Force Resolution

1/10,000 (23 bits)

Test Stroke(w/o grip)

800 mm

Speed Range

2.0~500.0 mm/min (adjustable)

Data sampling rate

Max. 1200 Hz

Motor

DC Motor

Dimension

94 x 53 x 144 cm

Weight

30 kg

Feature

1. Loadcell automatic reading, can be calibrated without installed on machine

2. Standard display for quick operation

3.Power supply 110-240V available

Accessories

Display Panel (standard)

-7" color touch TFT display panel.

-Supports Chinese, English, Japanese display.

-Displays force, pressure, displacement, and time.

-Can perform test condition setting: test speed, direction, auto-return, stop at the break point.

-Can analyze max. force, interval force, force at break point, and so on.

-Provides multiple stopping point settings: force, displacement, time, and elongation.

-Supports over travel, overload, overtime stop protection settings.

-Save up to 50 test results; supports saving to USB.

-Able to restore the machine to factory setting.

-Able to calibrate under stand-alone mode.

-Supports switching between Metric and Imperial units.

QC-551 Long Extensometer

QC-551 Long extensometer is suitable for higher than 20% elongation of rubber, plastic, PE, fabric, webbing of material which are high elongation measurement accessories. The specimen usually made dumbbell-shape. The extensometer can link with Cometech machine and auto-detect the deformation of the test piece during the test.

QC-557 Short extensometer

QC-557 Short extensometer can measure metal, hard plastic of less than 100% elongation of material deformation. During test, it can measure complete test deform rate and do not need to dismantle it when during the test. When the specimen gauge length is longer or elongation rate is bigger, customized longer extensometer is also available.

Portable Printer

Can print out results under stand-alone operation mode.

Software functions

-The data sampling rate is up to 1200 Hz..

-Analyze data.

-Windows system required.

-Chinese, English, Japanese, Korean, Spanish are available.

-Operation Mode: TCP/IP two-way transmission to connect with PC.

-Can import multiple test data and display at the same time.

-Supports Metric and Imperial units switching.

-Provides a flexible table for data analysis.

-Can name the data results.

-Data can be shown through the table, graph, or both.

-Data processing: save, import, list, statistical comparison, and so on.

-The X-Y axis of the graph can be set as force, elongation, displacement, time, stress, strain, and so on.

-Tensile, compression, bending, peeling and others are available.

-Supports over travel, overload, over time stop conditions as machine protection.

Related Machines

Related Grips

Related Services

-

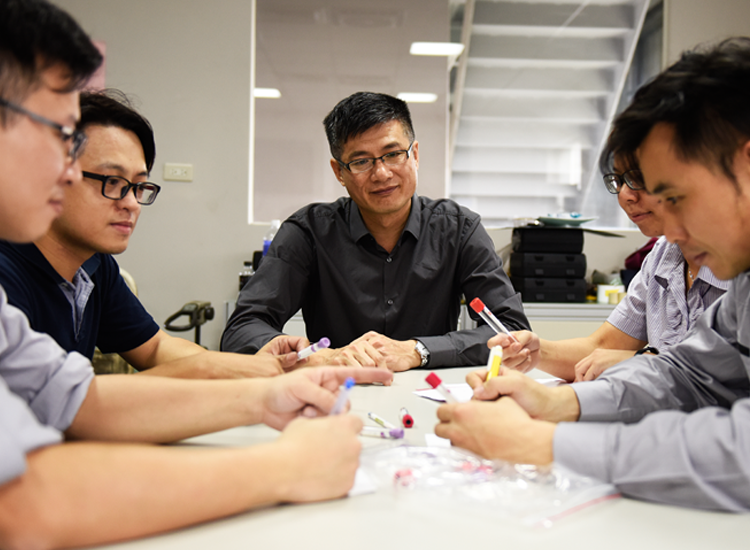

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

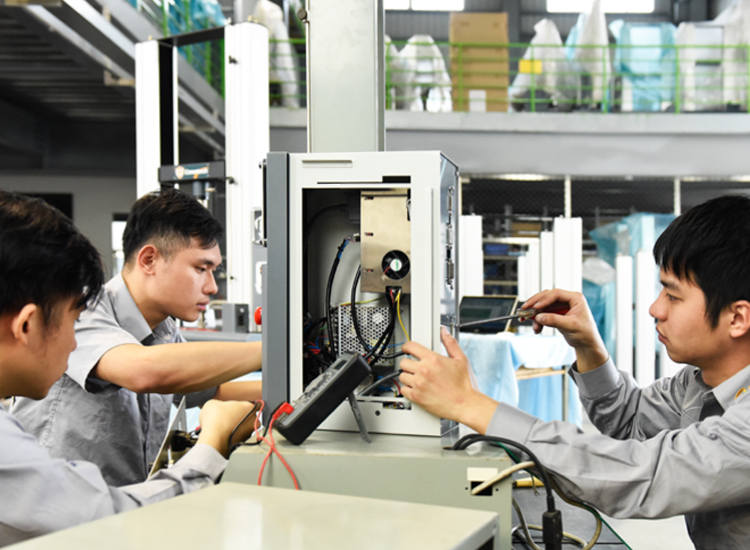

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE