Description

QC-528D3 Tensile Testing Machine equipped with a 2.8-inch touch panel, offering an intuitive user interface with versatile functions and ease of use. The machine can display real-time force variations and supports recording and retaining the maximum force value, along with a graphical test curve for easy and comprehensive monitoring of test data.

This model features a DC motor design, which not only enhances operational safety but also adapts to a wide voltage range, providing greater convenience for users. In addition, the tensile testing machine's speed can be flexibly adjusted according to testing requirements, ensuring high accuracy of test results and fully meeting the needs of diverse testing applications.

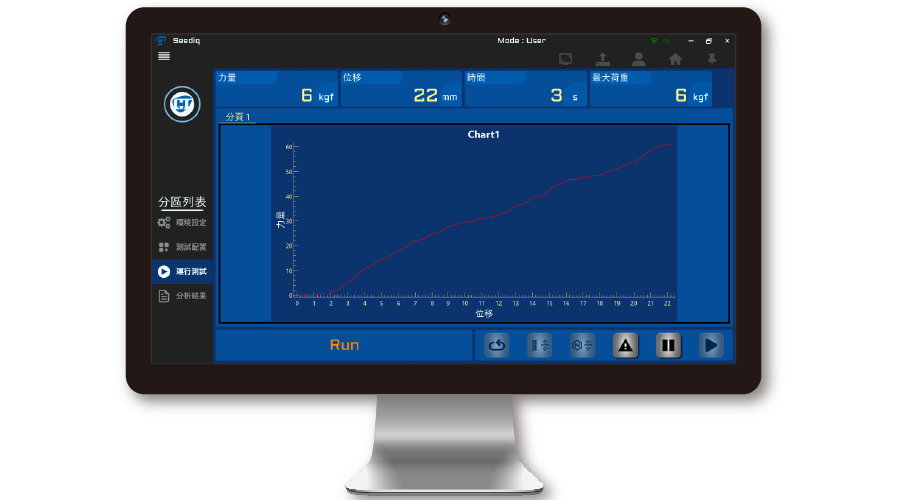

With the optional testing software, the machine can establish bidirectional communication and operation with a personal computer. It supports a variety of testing and analysis needs, including tensile, compression, bending, peeling, and adhesive strength tests. The system offers multilingual display and the ability to switch freely between metric and imperial units. Equipped with a comprehensive data analysis platform and diverse testing modules, it enables precise and efficient testing operations to meet various testing requirements.

Conform to Standards

- ISO 7500-1

- ASTM E4

- ASTM D-76

- DIN 5122

- JIS B7721/B7733

- BS EN 1002-2

- BS 1610

- GB/T 228

Industry

Paper, Adhesive tape, Electronics, Medical, Packaging, Food industries.

Catalog Download

QC-528D3 Universal Testing Machine

Specifications

Capacity

200N

Test Stroke

400 mm

Data sampling Rate

50 Hz

Speed Range

2-500 mm/min

Motor

100W 24V DC Motor Drives

Dimension

50*27*82 cm

Weight

27 kg

Features

1. Simpler Operation with Various Functions

Compact and lightweight, the machine is easy to carry and move to wherever testing is needed. It’s ideal for handling small samples and is well-suited for industries such as electronics, food, and pharmaceuticals. The system supports a wide power input range of 100 - 240V, reducing restrictions caused by different regional power standards and making the machine more flexible and adaptable to various environments.

2. Digitalized Speed Testing

A dedicated closed-loop motor driver delivers precision close to that of a servo motor. Test speeds can be set digitally, allowing for a wide range and highly accurate speed control.

Software functions

1.Data Analysis

2.Operating platform: Windows operating system

3.Color display with support for Chinese, English, Japanese, Korean, and Spanish languages

4.Operation mode: TCP/IP interface for computer connectivity

5.Simultaneous output of multiple test results

6.Selection of units available in both metric and imperial systems

7.Flexible table layout allowing customization of data positions

8.Customizable naming for data

9.Test screen display test values, curve graphs, or both

10.Data processing: save, import, list, statistical comparison, etc.

11.Curve graph settings include force, elongation, displacement, time, stress, strain, etc.

12.Capability for testing tensile, compression, bending, peeling, and other tests

13.Software protection features including over travel, overload, and over time stop condition

Related Machines

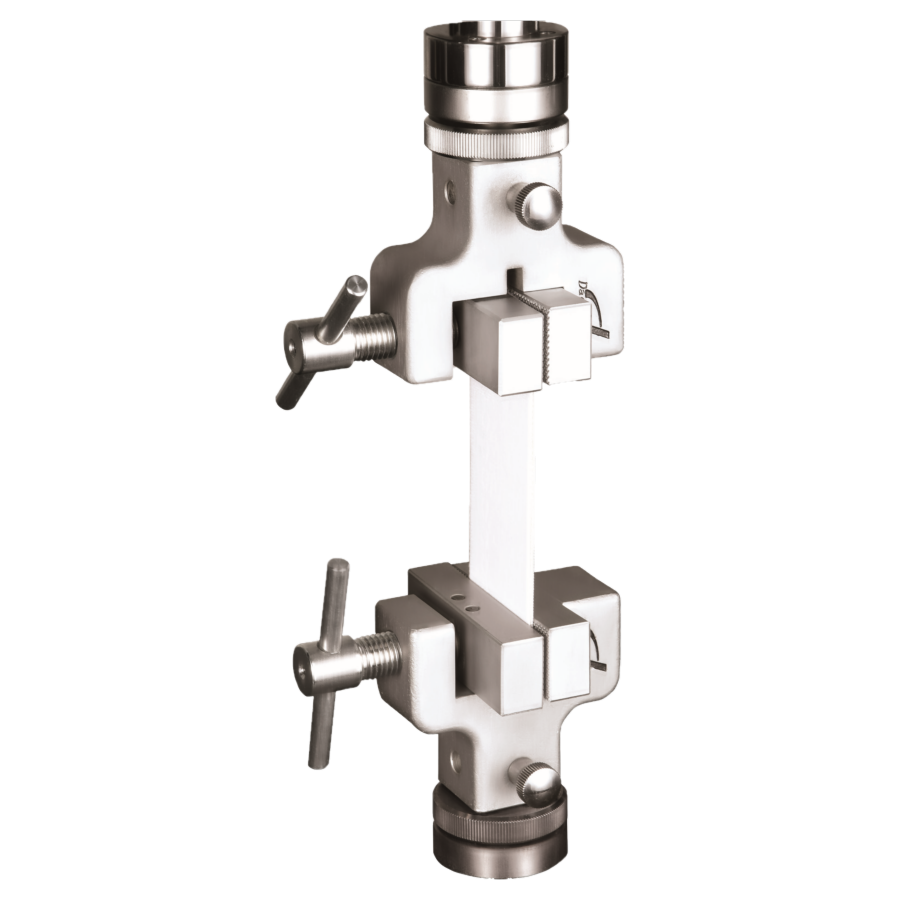

Related Grips

Related Services

-

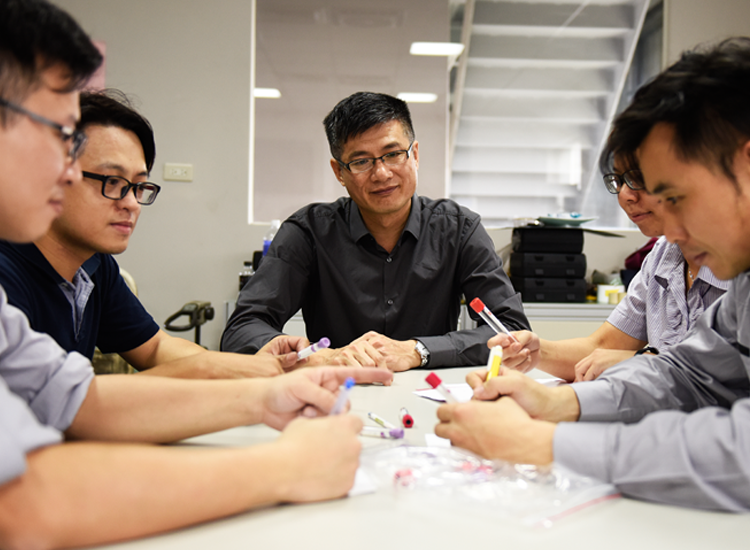

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

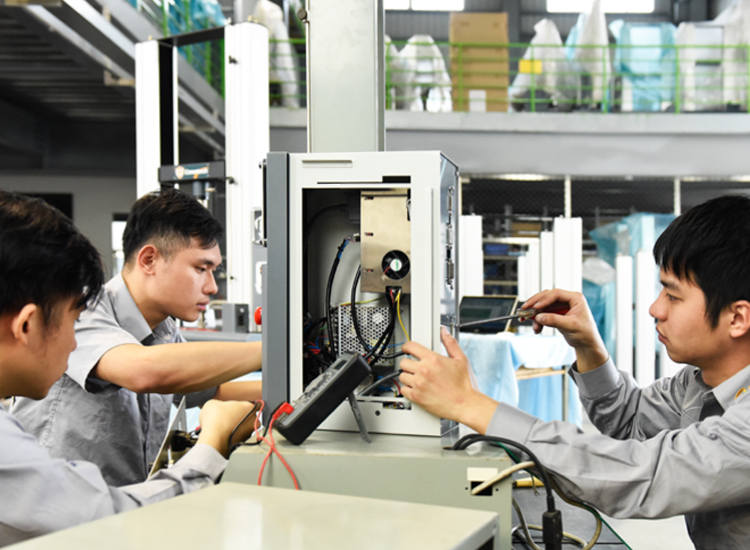

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE