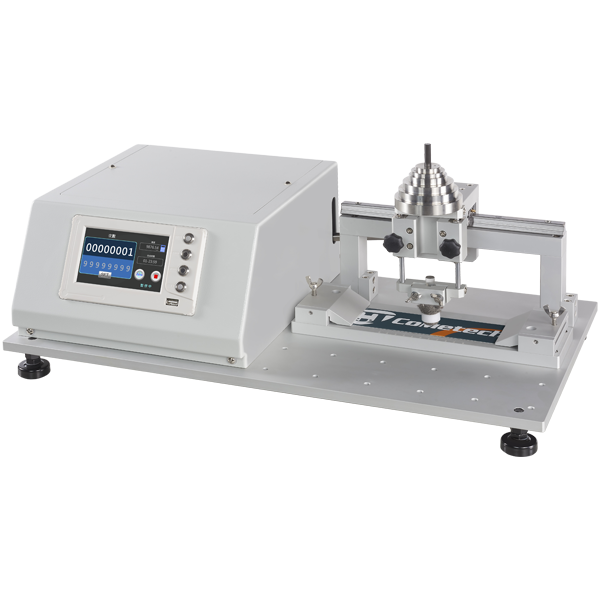

Description

Salt Spray Tester is used for testing parts rust-proof ability that had been through surface treatment such as electroplating, coating, anodizing, etc. With misty form’s salt water to speed up corrosion, in an attempt to test specimen rust-proof ability in short time, this tester is suitable to use in hardware, screw and electroplating industries and research organizations, etc.

There are three types of tests: Neutral salt spray test, Acetic acid spray test and Copper Speed up Acetic acid spray test. Three test specimens are needed or according to agreement. Vertical Suspending specimens or with vertical line as 15-30 ゜ to put in test chamber, specimens interval should not below 20mm, liquid drops on brace should not drop on the specimens, set required time to proceed with test and after finishing, use flow cold water wash specimen surface deposited salt, examining surface and levels after drying.

Conform to Standards

- JIS D 0201

- JIS Z 2371

- JIS H 8502

- JIS K 5400-1999

- ISO 9227

- ISO D 0205

- ISO H 8681

- ASTM B 117

Industry

Metal industry, Aerospace product manufacturing

Catalog Download

Salt Spray Tester-QC-711M/L

Specifications

Model

QC-711M/L

Required Collecting Cup

M: 1 pc

L: 2 pc

Power of Heater

M: 1000W

L: 2000W

Temp. Range

Chamber: room temperature ~ 50°C

Air:room temperature ~ 63°C

Machine Functions

Temp. Accuracy: ±0.5°C

Air Pressure: 0.8 ~ 2.0 ± 0.1 kg/cm²

Spray volume: 0.5 ~ 3.0 ml/hr

Salt Spray: 6.5 ~ 7.2 ml/hr

Cupric Acetate: 3.0 ~ 3.2 ml/hr

Material

Exterior: PVC, PP

Interior: PVC, PP

Systems

Salt Solution: Salt Spray, Cupric Acetate

Heating: Titanium alloy Heater

Control: PID Digital electronic + SSR control

Safety system

Circuit system load protection, over heating load protection, insufficient medicinal liquid protection

Power

Single phase 220V, 50/60 Hz

Internal dimension

M: 60 x 40 x 45 cm

L: 90 x 50 x 60 cm

External dimension

M: 109 x 110 x 90 cm

L150 x 124 x 105

Weight

M: 90kg

L: 120kg

Related Machines

Related Services

-

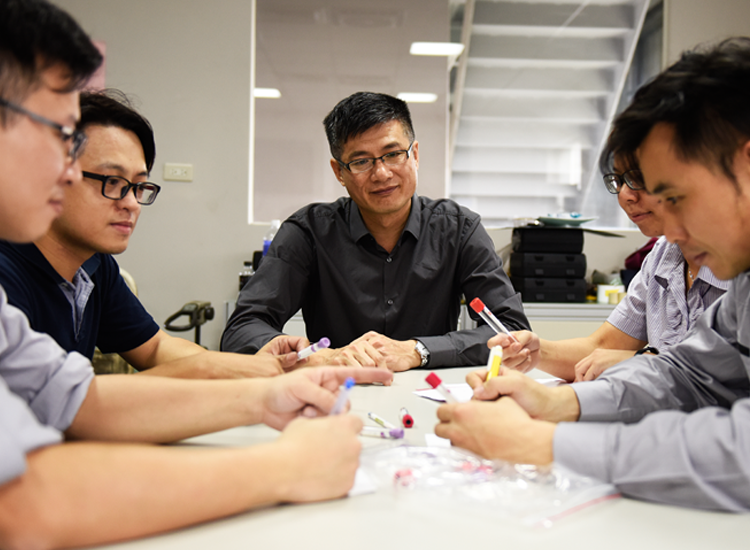

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

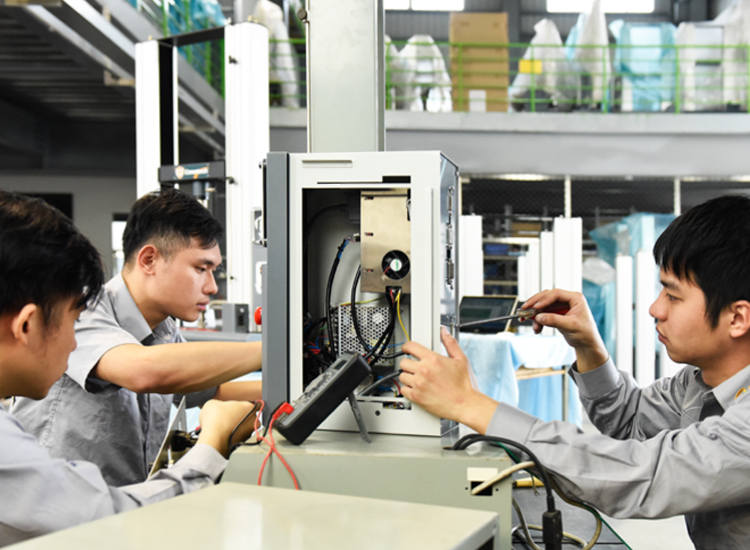

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE