Description

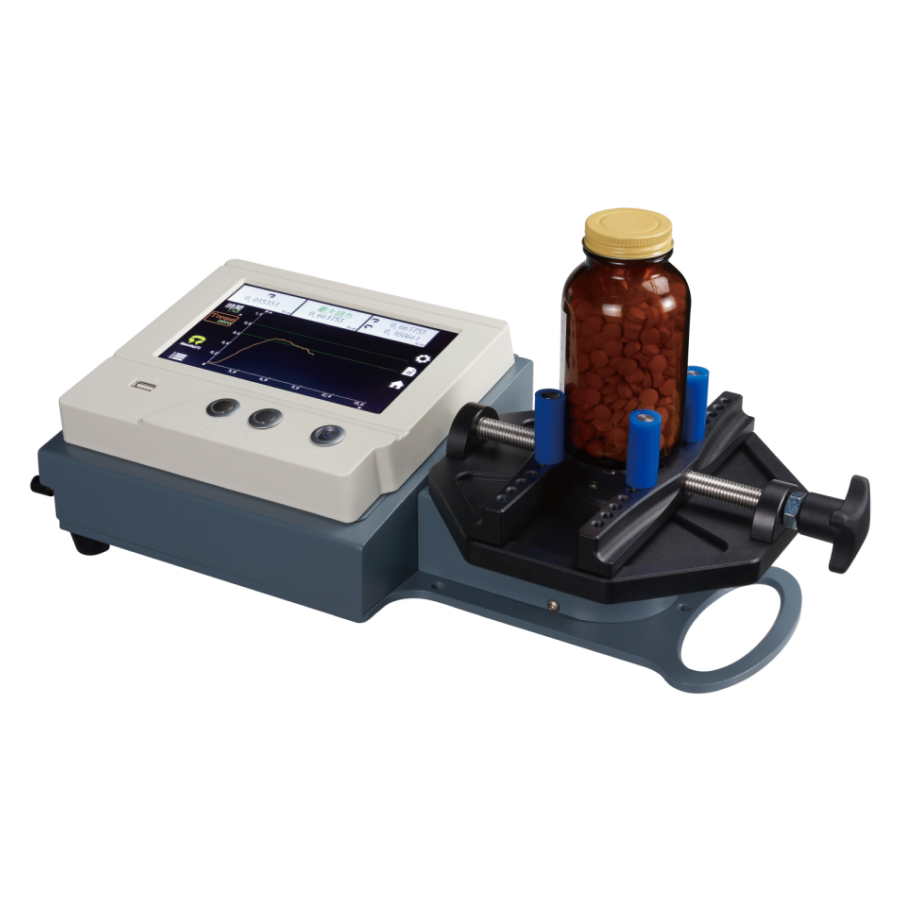

Torque Tester - Manual Type measures the twisting force, commonly used on products with bottle caps. The torque gauge can test both torsion of clockwise and counter-clockwise direction. The clamps of torque testing machine are adjustable fixture and quick drilling screw which can clamp round shape, square shape, or irregular shape samples. Test graph will be displayed during test to show real time condition.

Containers of round or irregular shapes with diameter of 10-190mm can clamp bottle caps quickly and securely. Customization of clamps is also available for torque testing on various speicmen such as torque wrenches, screwdrivers, electric tools, or even applied on cosmetic containers, pill bottles, torque spanners, etc.

Catalog Download

Manual Torque Tester Catalogue

Testing Video

Specifications

Measurement Range

0~10 N-m, 0~100kgf-cm, 0~90lbf-in (other capacity for optional)

Display Resolution

0.001N-m

0.01kgf-cm

0.01lbf-in

Container Diameter

Ø10~190mm

Units of Measurement

N-m, mN-m, N-cm, kgf-cm, gf-cm

lbf-ft, lbf-in, ozf-in

Analysis Item

Max. Torque Value, 1st Peak, 2nd Peak (clockwise and counter-clockwise)

Sampling Rate

1200Hz

System Accuracy

±1% of Max Capacity

Overload

150% of Max Capacity

Power

Single Phase 100V~240V

Dimension

45x19x13.6cm

Weight

5.6kg

Accessories

Display (standard)

-Equipped with 7" touch display for setting and operating

-Language: Chinese, English, Japanese, Polski

-Able to analyze the max. torque, first peak and second peak

-Real-time display the forward and reverse torque value

-Able to set the upper and lower limit of test result

-Plug in the USB to record the whole raw data during the test

Torque Hand Tool Grip

Test grip can be designed according to requirement

Software functions

(Software is for optional)

-Data sampling rate is at 1200Hz Max.

-Operation way: By keyboard and mouse operating the software interface

-Compatible with Windows system

-Language for selection: Chinese, English, Japanese, Korea, Spanish, Portuguese

-Operation mode: TCP/IP interface connection, and software control the operation of machine directly

-Various units including Metric and Imperial units

-Flexible form to manage database

-Free to name the data, and supporting self-determine formula data analysis

-Test page showing test curve and real time data at same time

-Data processing: save, load, list and compare data

-Supporting graph X-Y axis amount adjustment, marking for specific spot, marking for range, etc.

-Software protection: Over displacement, over load, over time, Max. torsion drop auto stop

-Test settings can be modularized to reduce human error

-Helping getting important data by self-setting upper/ lower limit of data

Related Machines

Related Services

-

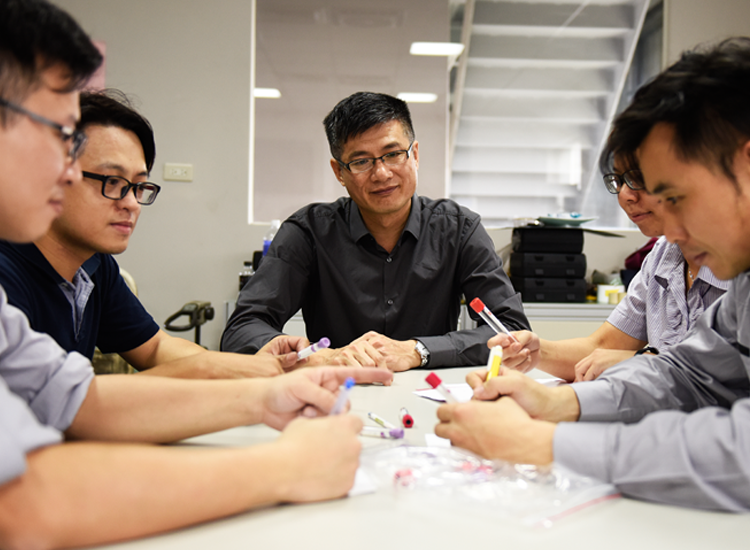

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

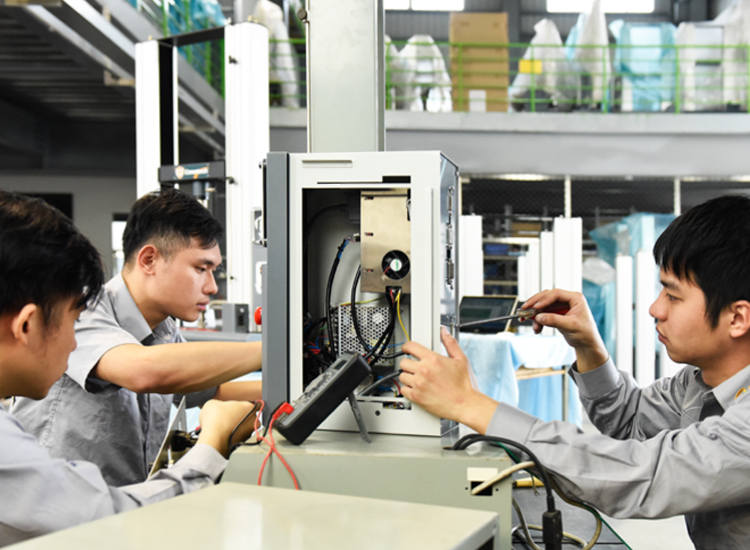

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE