Description

Melt Flow Index Tester can test thermoplastic melt mass flow rate (MFR) and melt volume flow rate (MVR), also known as MI or MFI. The Flow Indexer QC-652B can perform ISO/ ASTM standards test methods, equip with touch panel that guide user to precisely and smoothly proceed with test. The melt flow tester also has analysis function and flash drive save function.

Optional accessories can be selected according to different materials properties for melt flow testing, such as high flow material block mechanism or MVR volume test mechanism to proceed with various tests.

Conform to Standards

- ASTM D1238

- ASTM D3364

- ISO 1133

- GB/T 3682

- GB/T 9643

- JIS K6719-1/2

- JIS K6921-2

- JIS K6922-2

- JIS K6923-1

- JIS K6924-1

- JIS K6926-2

- JIS K7210

Industry

Plastic, Medical Product, Mask

Application

ASTM D1238,ISO 1133 Melt Flow Index

Catalog Download

QC-652B Melt Flow Index Tester

Testing Video

A Method (MI, MFR)- Melt Flow Index Tester QC-652B- ASTM D1238, ISO 1133

Specifications

Use Temperature

B Type: 50~300°C

C Type: 50~400°C

D Type: 50~300°C(Corrosion)

E Type: 50~400°C(Corrosion)

Counter Resolution

0.01s

Piston Push Rod Weight

100g

Automatic Cut

Interval time 1~300 seconds can be set

Heater Size

9.55mm±0.01mm

Hole Mold

2.095mm±0.005mm

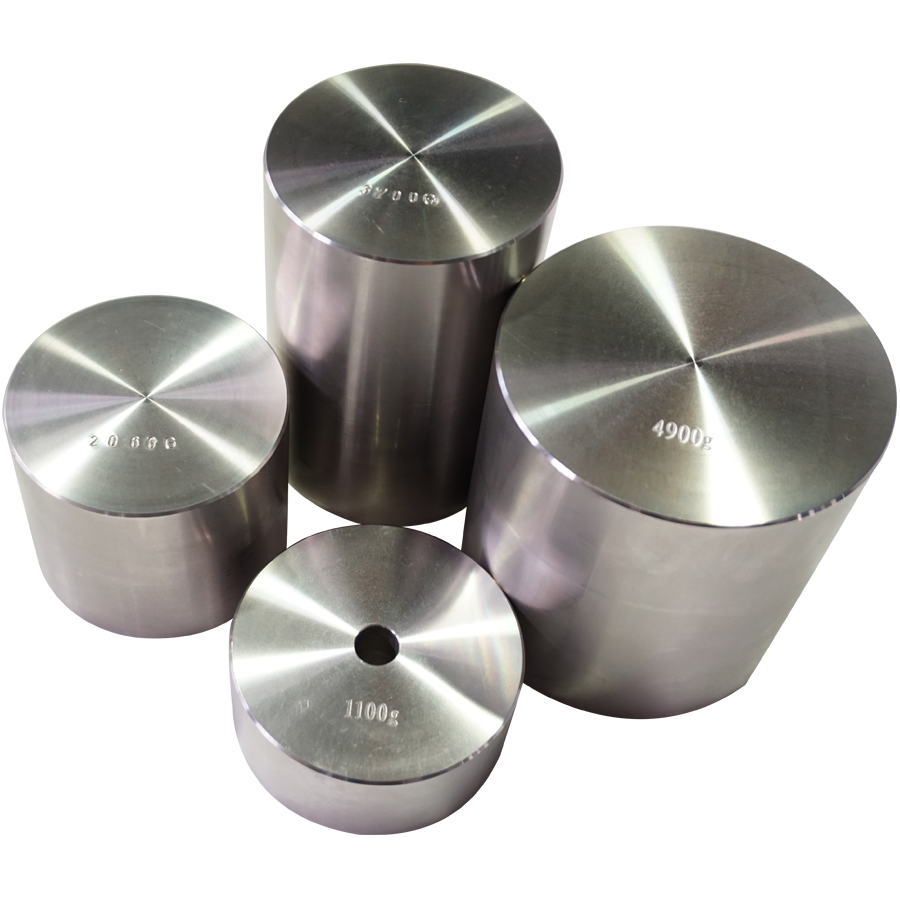

Counter Weight

Standard stainless steel weights(optional) , weights can also be customized.

Accessories

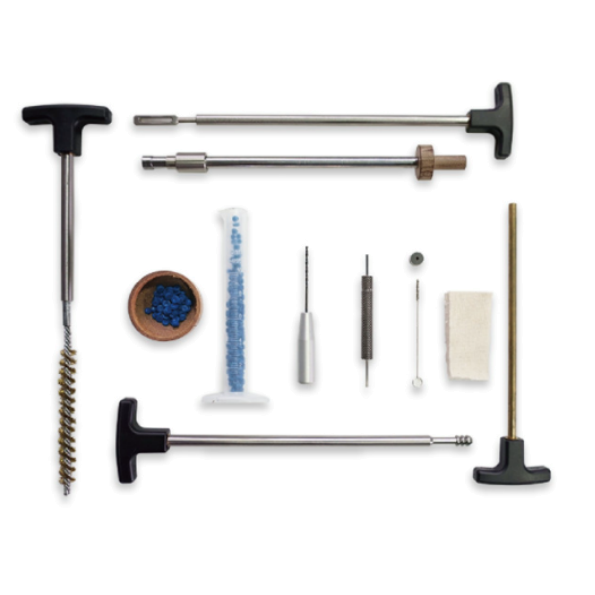

Cleaning brush, measuring cups, funnel and Die calibration plug gauge

Weight

40kg (machine weight)

Dimension

47x38x48 cm

(47x38x60cm with MVR part)

Optional Accessories

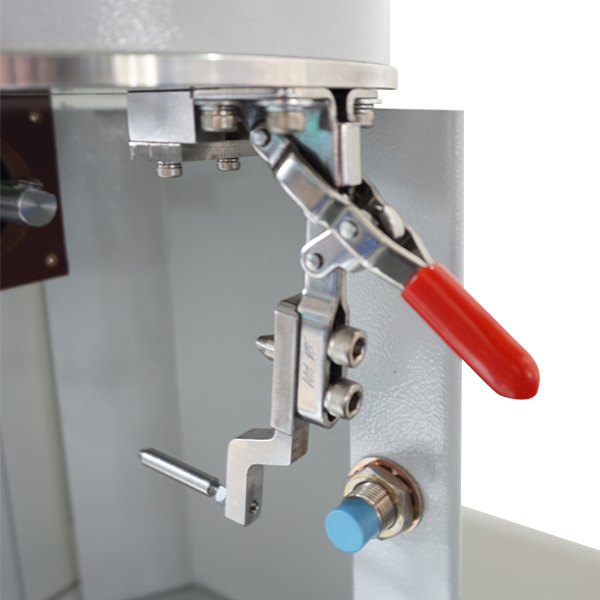

1. High MI value material block mechanism

2. MVR test mechanism

Power

220V Single phase 50Hz/60Hz, 7A

Accessories

Standard Accessories

These are standard accessories.

Die, cleaning brush, measuring cups, funnel, Die calibration plug gauge.

Weight

The commonly standard weights include specifications of 1100g, 2060g, 3700g, 4900g, 9900g,12400g,19900g,21500g, which can also be customized.

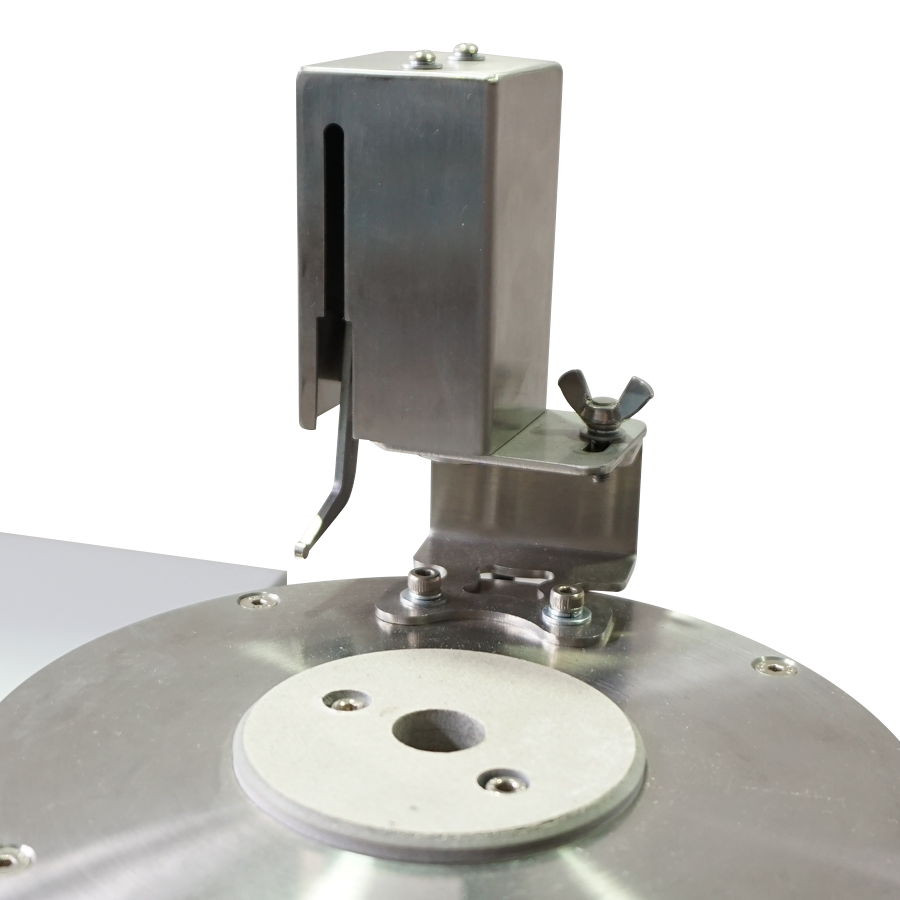

MVR

MVR is used for volume measurement(B method), equipped with calibration parameter memory function.

High MI value material block mechanism

Used for high MI value plastics, prevent plastic flow during preheating.

Related Machines

Related Services

-

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE