Description

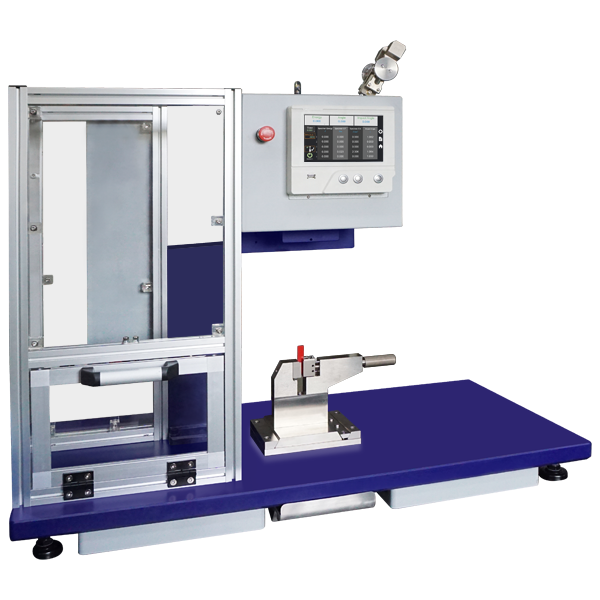

Impact Tester Digital Type can measure the impact resistance of polymer materials. It calculates the absorbed impact energy based on the energy conversion relation. The precision of the impact hammer will highly affect the speed and mass position when impact, and this might influence the test accuracy.

QC-639S/T is equipped with 7" PLC touch screen. The machine encoder detects the angle for calculating the energy, and the built-in correction system compensates the loss causing by the friction of wind resistance. The optional dedicated software can support various analysis functions, record, generate reports, etc. Izod and Charpy are the most common test methods. This machine can change the hammers and vises rapidly to satisfy different test methods and standards (ASTM & ISO).

Conform to Standards

- ASTM D256

- ASTM D6110

- ASTM E23

- ASTM D4812

- ISO 179

- ISO 180

- ISO 13802

- ISO 8256

- ISO 148

- EN 10045-1

- ASTM D1822

Application

ASTM D256, ASTM D6110, ASTM E23 ,ISO180, ISO 148, EN10045-1, ISO 179, ISO13802 Pendulum Impact Test

Catalog Download

QC-639V(W) Digital Impact Tester

Testing Video

Specifications

Model

QC-639V / QC-639W

Test Method

Izod, Charpy

Initial Angle

150°

Test Capacity

QC-639V:

Izod 1-12J

ASTM Charpy 1-12J

ISO Charpy 1-5J

QC-639W:

Izod 1-25J

Charpy 1-25J

(50J Optional)

Angle

Min. display angle 0.05°

Accessories

Hammer calibration report, Manual, Hex Wrench Set

Optional Items

1. Different capacity impact hammers and the vises for different standards.

2. QC-640A Impact Specimen V-notcher.

3. Optional analysis software.

Power Supply

110~240V / 3A

Dimension

V / W

Full Cover 110x50x110 cm / Full Cover 110x50x117 cm

Half Cover 110x50x77 cm / Half Cover 110x50x84 cm

Weight

V / W

Full Cover 290 kg/ Full Cover 370 kg

Half Cover 260 kg / Half Cover 340 kg

Accessories

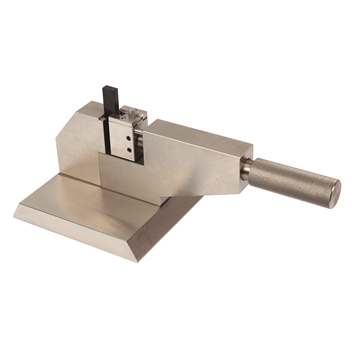

Izod Vise

Vise for Izod test

Izod Hammer

Hammer for Izod test

Charpy Vise

Vise for Charpy test

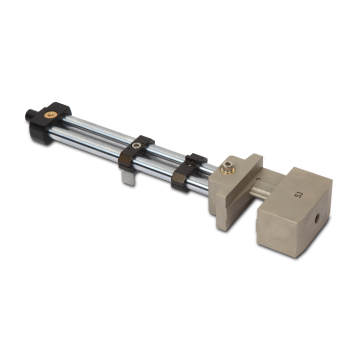

Charpy Hammer

Hammer for Charpy test

Software functions

1.Test Data can be out put to .csv format (open with excel)

1.Test Data can be out put to .csv format (open with excel)

2.Test setting, hammer and vise specification is build in the software, users do not have to input them one by one.

3.Can check the energy loss, and add it back.

Related Machines

Related Services

-

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE