1. Adopted with 7- inch of TFT Color touch screen

2. Chinese, English, Japanese, Three different languages can be selected.

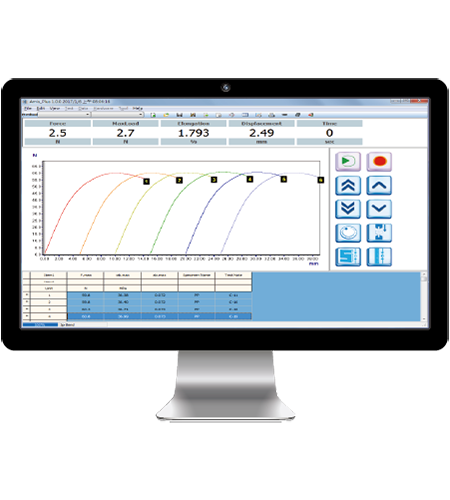

3. Data Display: Force, Stress, Torque, Displacement, Time

4. Test setting, can set test speed, test direction, automatic position return, breaking point machine stop.

5. Data analysis, can read the maximum force, internal force, breaking point force and so on.

6. Can be stand-alone calibration.

7. Various machine shutdown conditions setting (force, displacement, time, elongation).

8. Can be restored to the original factory state.

9. Unit selection can be Metric unit, Imperial units.

10. Over-travel, overload protection and overtime machine stop

11. Can store up to 50 data, USB storage data function.

12. Support multiple sets of signal sources.