Description

Manual Hot Press QC-677T is in small size occupying no space. The heating plates can adjust the parallelism due to the four-column construction design, and this design improves the machine rigidity. QC-677T has two independent heating plates, users can clamp the plates through the hydraulic cylinder with a split-type pump. It can be used for preparing development usage's sample, color-matching plate, or flattening specimens, convenient for factories to produce materials accordingly. Equipped with our F1C controller, the tester provides a simple setting interface, clear value display, temperature and test time for user easy understanding the test progress. Through the real status showing on the display, user can control the molding process and reduce the human operational error to produce specimens with stable quality.

Suitable materials include: conjugate fiber, silver solder, indium powder, carbon black powder, thermoplastic, thermosetting plastics, polytetrafluoroethylene, ceramic material, metal bonded sample, etc.

Industry

Rubber, Plastic

Application

ASTM D790, ISO 178 Bending test

ASTM D638 Plastic Tensile Test

ASTM D412 Rubber Tensile Test

Applications of Thermo Molding Machine

Catalog Download

QC-677T Manual Hot Press

Testing Video

Specifications

Model

Desktop Model

Capacity

50/100KN

Heating Plate Area

150*150mm

Distance Between Heating Plate

0-80mm

Temperature Range

50-300℃ (400℃ model is optional)

Heating Rate

Room Temperature~250℃ 15 min

Cooling Method

Circulation Cooling for upper and lower heating plates

Temperature Display Discrepancy

±1℃ (Above 300 ℃±3℃)

Heating Plate Uniformity

200~300℃±2℃

Under 200℃±1.5℃)

Force Range

Maximum pressure range 10-90%

Force Resolution

0.1KN

Operation Method

Pressurizing with a manual hand pump

Real-Time Display

Real Time Display, Force, Stress, Upper and Lower Hating Plate Temperature, Graph, Time

Accessories

100*100mm*2mm mold

Width (W)

50/100KN-725mm

Depth (D)

50/100KN-650mm

Height (H)

50/100KN-725mm

Power Consumption

20A

Power Supply

Single phase 220V/50 or 60HZ

Weight

110KG

Accessories

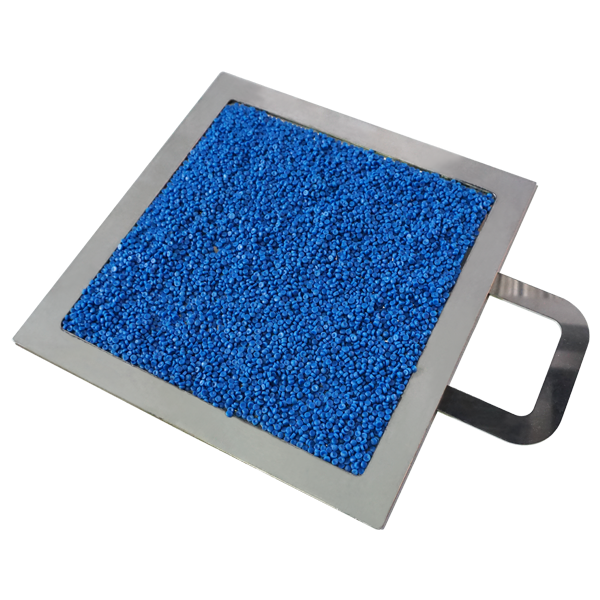

Forming Mold

Standard forming mold 250 x 250 x 2(thickness) mm. Size can be customized.

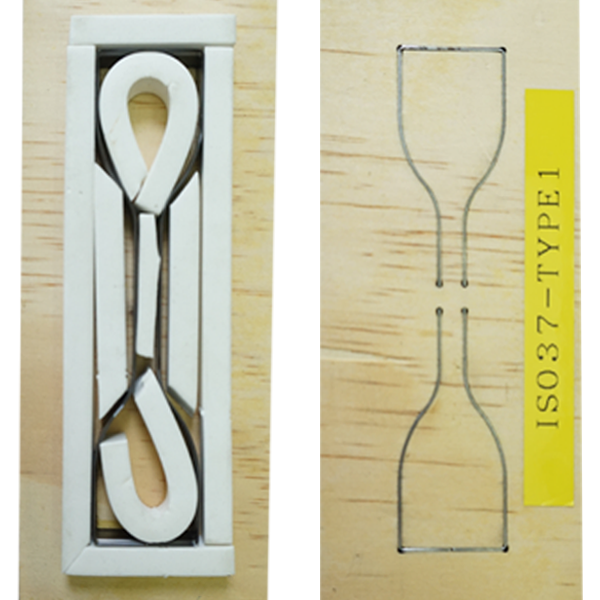

Cutter (A type)

(Optional) Standard cutter or customized cutter

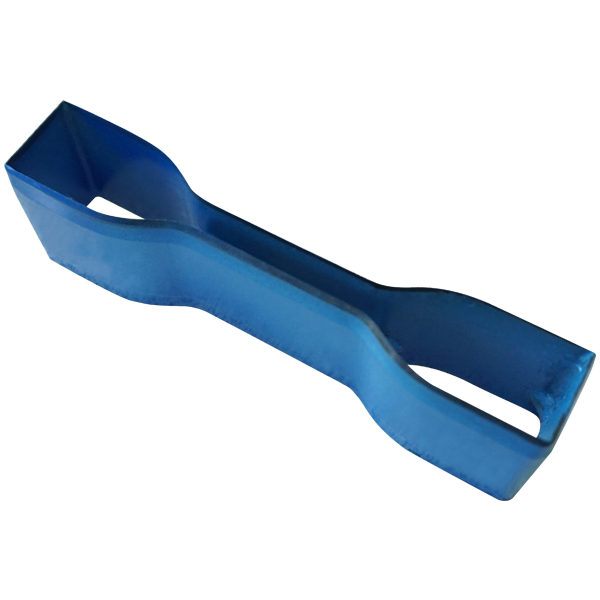

Cutter (B type)

(Optional) Standard cutter or customized cutter

Related Machines

Related Services

-

Test Planning

Specialists would evaluate the preliminary testing result, choosing the best machine for your test planning. We will provide complete solutions which make you free of worrying about the unknown machines.

READ MORE

-

Training

The professional engineers with rich experience will personally train and provide complete training content. Your operators and developers can learn the technical skills of various material testing machines from novice to expert.

READ MORE

-

Maintenance Service

We provides free maintenance during the warranty period to ensure perfect after-sales service. Our ERP warehousing system makes users quickly obtain the required parts for standing maintenance within 10 years after the sale.

READ MORE

-

Calibration & Certification

Our company received CE certification from TUV. From design to manufacturing, all the products follow the CE standard rules. A high-level calibration is utilized to ensure the accuracy and stability.

READ MORE

-

Customize Service

The software is self development. R&D team independently develops its own software programs which has high integration capability and scalability to add new analysis items and meet various testing needs.

READ MORE

-

Update & Upgrade

We can help you update the software and hardware. Old model upgrading is also available, which could improve the efficiency and extend the machine service life.

READ MORE